The compact and functional design of our Kart test benches has been specifically thought of and created to respond to the needs of the best professional tuners.

Created thanks to many years of experience in the motorbike sector, the system allows to carry out accurate checks of engine performance thanks to the wide range of results provided by the associated software and electronics.

Patented Design

These engine power test benches have been built to allow testing of any type of go-kart engine to be carried out.

The latter, after being removed from the vehicle and fixed on the appropriate engine support, must be connected to the acceleration system of the bench, so that it can be manoeuvred by the commands on the console.

The test bench is equipped with:

Specifically designed and manufactured by Easyrun Technology for:

Use of the test bench:

Analysis of the results allows:

Patented Design

The power test bench for go-karts and Scooters is built so as to allow testing of go-kart, Scooter and motorbike engines without removing them from the frame.

The bench is equipped with adjustable supports for go-kart frames, which allow to adjust to the different dimensions of the go-kart frames, allowing them to be blocked safety.

There is also a a sliding wheel block to be used when the bench is testing motorbikes or scooters.

The bench is also equipped with 1 main roller that acts as inertial mass, as well as a secondary roller with variable ratio for inertia adjustment. The bench allows to carry out the indirect measurement of the torque and power of the engine of the vehicle by means of roller acceleration calculation detected by means of sensors and data acquisition systems.

The mechanical structure has also been designed and made with the highest criteria regarding safety, mechanical strength- and ease of use.

Specifically designed and manufactured by Easyrun Technology for:

Use of the test bench:

Analysis of the results allows:

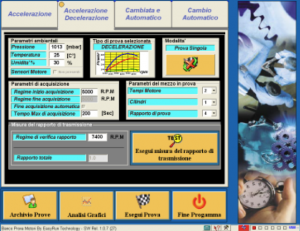

Starting from the USB acquisition card designed and produced by EasyRun Technology for benches not only of its own production, the software ProJMotor allows to measure the performance of vehicles with internal combustion engines.

The high level of accuracy and high number of measurements that can be carried out per second by the electronics equipped with the latest generation of chips, allows to obtain extremely precise curves in which even the minor dynamics of elaborated engines can be detected.

Some features:

It is easy and intuitive to use, the buttons change colour, indicating the following button to be clicked. (Test reports are available in just three steps).

It can be controlled from a distance by means of a remote control device, without leaving the vehicle.

It allows to print all sizes of graphic reports the report also includes the logo of the workshop.

All tests are filed in an efficient database that allows to manage all tests, classifying them as per customer and technical characteristics of the vehicle etc. (No need to look for tests in folders with stored files)

It allows to create graphs and compare an unlimited number of curves read from the database that is assigned a different colour. This allows to assess the changes and improvements before and after changes. An automatic pointer measures the difference between two curves across the graph.

An automatic pointer provides precise measurement for each type of curve that can be displayed.

It allows to correct the curves as per weather conditions.

The measuring unit for power (Kw, Cv), torque (Kg *m, N*m) etc.. can be selected according to the one more familiar to the tuner who uses the bench.

Possibility to acquire sensors and control relay outputs.

TYPES OF TESTS THAT CAN BE CARRIED OUT

(Rapid test to measure the power delivered to the wheel and assess carburating problems, power dips, etc.)

(To also assess the power absorbed by the kinematic chain of the gearbox, transmission and tyres).

(To assess the power “available” for the different gears, due to the different power levels absorbed by the gears).

(To assess the power with vehicles equipped with automatic gearbox or variator, such as cars and scooters).

The following measurements are obtained from the four tests:

Curves that are graphically represented and comparable are: